TPE or silicone? Which should you choose?

SiliconeDolls24.com informs about experiences with TPE & silicone dolls

TPE = Thermoplastic elastomers

Thermoplastic elastomers (also known as elastoplastics; abbreviation TPE) are plastics that behave in a similar way to classic elastomers at room temperature, but deform or can be deformed plastically when heat is applied and therefore exhibit thermoplastic behavior.

Before we tell you how these Chinese love dolls made of plastic are and you read yourself a wolf, we openly admit that we stand behind our absolutely high-quality and at first glance unfortunately also somewhat expensive silicone dolls / the so-called real doll productions without compromise, not only because we earn our money with them, but because these higher-quality models, fortunately for our customers, achieve an extremely higher rank in durability, reliability, suppleness, robustness and much more. The models made from TPE simply cannot keep up.

Many customers spent a lot of money on TPE dolls because they thought they had bought a beautiful and durable "real doll", but they were in for a rude awakening all too soon. The beauty of the model was gone all too quickly because only the slightest first-time mistake had been allowed on these models.

Of course, it hurts all the more when you realize far too quickly that you had mistakenly backed the wrong horse. To make matters worse, many manufacturers of TPE models have deliberately refrained from including a comprehensive manual or adequate care instructions with the TPE model they have just purchased.

OK, we cannot yet look into the brains of these or those producers, but the company MECHTECH (owner of the SiliconeDolls24.com website) with its DreamDoll & InridiDoll productions has been sending a comprehensive manual (DE/EN) with a purchased model since the start of production of the first model, but only because we explicitly want our "exclusive clientele" to achieve longevity with our models. If handled correctly, a Silkion model can definitely get older than 10 years without anything seriously going out of shape; which does not seem to be the case with thermoplastic Real Doll models! More on this later.

SILICONE Vs TPE?

HERE YOU WILL FIND A TRANSLATION FROM OUR DREAMDOLL MANUFACTURER ON THE SUBJECT OF "TPE OR SILICONE?"

Silicone Vs TPE: What should you choose, what is the right choice when buying a model? Several questions arise before you buy a so-called RealDoll model / love doll.

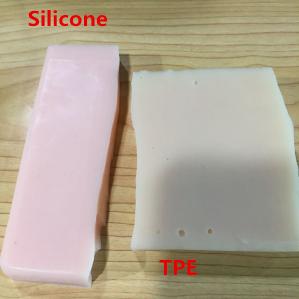

The main problem is often that the basic materials / raw materials used in a model offer you two solutions. For example, you see TPE on one side and silicone on the other. But what are the advantages of these two materials? What are they? Before you start a comparison, let's define the two elements in a little more detail:

Silicone consists mainly of the material oxygen and silicon. It is mainly used in medicine, cosmetics and mechanics. It is a certified skin contact friendly material (silicone). It is cast on a coated skeleton in a mold using the cold casting process.

TPE (thermoplastic elastomers) are chemically wide-meshed cross-linked spatial network molecules. The cross-links cannot be dissolved without decomposing the material. TPEs are materials in which elastic polymer chains are integrated into thermoplastic material.

It has a high elasticity and a thermoplastic character (which changes depending on the required heat input). TPE is injected hot into the mold and onto the skeleton (i.e. a model is virtually baked).

This inevitably results in a considerable difference in the materials; if you compare TPE with silicone! This is probably the most important aspect of our comparison. The two materials are as different as night and day! First of all, it should be noted that TPE is not a silicone and has nothing in common with the obvious and latent properties and characteristics of platinum cross-linked silicones.

Silicone is clearly the more durable material. This is due to its molecular structure alone, as the polymers present are only incorporated into the thermoplastic material in a small form. Silicone consists of almost 100% platinium cross-linked polymers, which unfortunately also have an impact on the purchase price of medical silicones. Silicone is cast cold (room temperature, not too cool) and does not foam up during casting.

TPE is more like a solid foam (similar to a sponge, with micro-pores), which is molded around the skeleton in the hot casting process and thus gives a model a realistic appearance. The skeletons are made with multiple joints and look durable. TPE, when acting with this material, has gotten the distinction of being flexible. It is said to be very comfortable during simple sex and at first contact and touch.